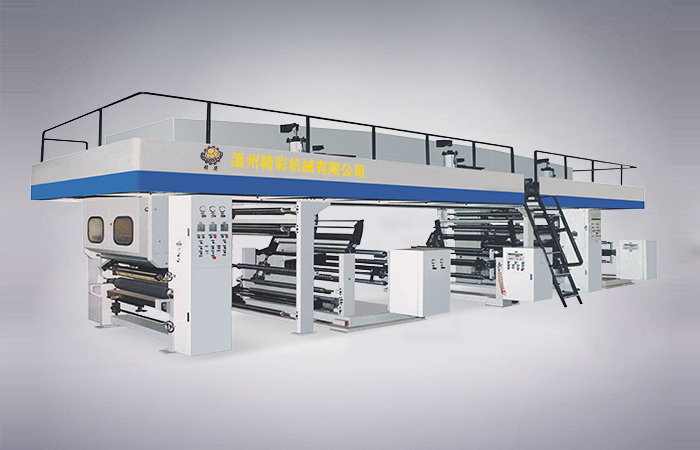

JSF-A Model Series· High-speed·Heavy Laminator

Use:

The machine is suitable for BOPP, PET, PVC, PE plastic film, paper, aluminum foil roll material.

Characteristic:

Unwinder Device:

Unwinder is featured by the independent driver rotary double-post. The laminating materials is fastened by the air shaft, Auto splicing. EPC

correcting system.

Rewinder Device:

Rewinder is featured by the independent driver rotary double-post. The laminating materials is fastened by the air shaft, in the form of centeral

rolling. Auto splicing.

Coating method:

Anilox Roller coating(Extra uniformity roller drive by the independent electrical motor)

Heating Oven:

Four-section air-impulsion oven, the whole oven is designed by the negative pressure with the large air flow and wind pressure for creating

the low temperature and large air drying,The passing roller inside is driven by the single electrical motor and transmitted by the synchronous

belt with the low noise(Outside the oven with EPC correcting system)

Laminating method:

It is featured by the three-roller, heavy type and compound for ensuring the resultant of forces, even surface and the application of S-shape chill roller.

Machine Control system that are optional:

Winder and both main motor use the import PLC controIAC vector converter motors, Four section closed-loop tension control and display

(Full machine use three sets EPC correcting system)

Unwinder is featured by the independent driver rotary double-post. The laminating materials is fastened by the air shaft, Auto splicing. EPC

correcting system.

Rewinder Device:

Rewinder is featured by the independent driver rotary double-post. The laminating materials is fastened by the air shaft, in the form of centeral

rolling. Auto splicing.

Coating method:

Anilox Roller coating(Extra uniformity roller drive by the independent electrical motor)

Heating Oven:

Four-section air-impulsion oven, the whole oven is designed by the negative pressure with the large air flow and wind pressure for creating

the low temperature and large air drying,The passing roller inside is driven by the single electrical motor and transmitted by the synchronous

belt with the low noise(Outside the oven with EPC correcting system)

Laminating method:

It is featured by the three-roller, heavy type and compound for ensuring the resultant of forces, even surface and the application of S-shape chill roller.

Machine Control system that are optional:

Winder and both main motor use the import PLC controIAC vector converter motors, Four section closed-loop tension control and display

(Full machine use three sets EPC correcting system)

Technical parameter:

|

Max. Laminating width |

600,800 ,1000 ,1200-1400mm (Max. Laminating materials width bases on the contract) |

| Coating Method | Anilox Roller(Shaft less by air cylinder) |

| Max Machinery speed | 200m/min (up to the Φ200mm Anilox Roller) |

| Diameter of Winder | Φ600mm,Φ800mm (Inner diameter of paper core is Φ76mm) |

|

Drying Method |

Electrical heating |

Related products

Heavy laminator machine